Last Updated on December 7, 2020 by Paul

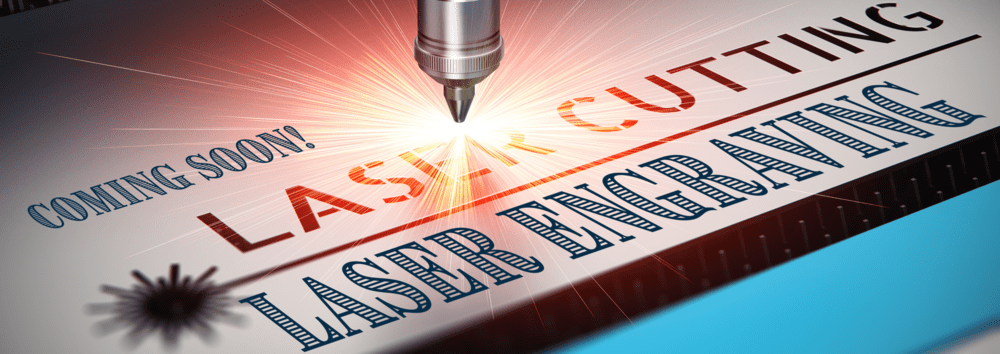

Laser Engraving Business and Customization

It’s an undeniable fact that modern technology has opened the door to new possibilities for the business world. The laser is amongst many inventions of modern science. It has played vital roles in almost all industries and businesses. Laser engraving is now one of the popular business methods that are highly attractive, demanding, and cost-effective.

At the same time, product customization or self-customizable products are becoming a widely accepted trend. Everyone now searches for something unique and personalized that reveals their personality to the world, and self-customization has succeeded in providing what they look for.

For this reason, perhaps, the popularity of the custom laser engraving business is increasing unimaginably. But, before we jump into an in-detailed discussion, let’s gather some general knowledge about Laser Engraving.

- What is Laser Engraving?

- Types of Engraving

- Customization In The Laser Engraving Business

- Products That Can Be Custom Laser Engraved

- Why Start a Customized Laser Engraving Business?

- Inkybay – a Customization Solution for Laser Engraving Business

What is Laser Engraving?

Laser engraving is a method of using lasers to engrave and mark on an object’s surface, especially for designing purposes. The process requires highly powerful laser engraving machines.

Laser not only cuts through metals but also capable of handling delicate medical surgeries that are undeniably a revolutionary contribution. Laser technology is used in many fields like aerospace, automotive, 3D scanning, heat treatment, medical devices, military and defense, media storage and access, optical storage, etc. The laser’s trajectory is implemented by computer software that is followed by a 2D image file of the design.

Types of Engraving

Laser marking and engraving differ from each other in many ways. Although, laser engraving is considered a subsection of laser marking and laser etching is a subset of laser engraving.

-

Laser Marking

Laser marking happens when a low-powered laser beam interacts with the surface of the target material to alter the appearance. It is mainly used for discoloration purposes, to create high contrast marking without damaging the property. The best thing about laser marking is that the material surface remains intact.

Four types of laser marking are seen in businesses nowadays – Annealing, Coloration, Foaming, and Carbon migration. Laser marking works perfectly for creating logos, QR codes, bar codes, UID codes, and any other identifications.

-

Laser Engraving

The laser physically cuts through the material surface, creating more like a cavity that eventually illustrates an image. Laser engraved images or designs can be seen and felt respectively through eyes and touch.

The engraving depth depends on the materials often. The laser engraving depth is a maximum of 0.020″. But upon a 3mm acrylic, the laser can cut deep around 0.01″ (0.25mm) and 0.020″ (0.5mm) in some timbers. But it’s better not to go deeper than this. Otherwise, there’s a high risk of damages like warping or excessive burn.

Depending on the material surfaces and the cutting target, engraving is three types – Etching, Laser ablation, and Deep laser engraving. Laser engraving works smoothly with any kind of metal, leather, plastic, wood, glass surface, and an even smaller object like jewelry. And the good news is that there’s hardly any chance of product damage or deformation. Perhaps, this is the reason laser engraving is widely accepted by people who want personalized or customized products.

-

Laser Etching

Through the process of laser etching, the laser beam produces enough heat that melts the surface of the material. The targeted portion melts and expands, resulting in raised marks with altered reflectivity and enhanced contrast. The etching depth is not more than 0.001″, and the process perfectly goes with polymers, ceramics, and plated metals.

Customization In The Laser Engraving Business

In the last 7-8 years, there has been substantial growth in the laser engraving industry. Customization or personalization in the laser engraving business was available only at industrial level production before. However, today – small businesses or vendors have succeeded in offering many laser-engraved products with a touch of customization.

Just take a look at the US-based eCommerce business website Etsy. Search using the keywords “laser engraved” and see the swarming of laser engraved personalizable products at Etsy stores. There are products like wood items, wedding glasses, jewelry, crafts, bags and purses, dog collars and tags, lather items, and many other daily life items like water bottles, pens, baby birth blocks, business cards, etc.

Small engraving businesses (sometimes remote or home-based) are becoming very popular nowadays. It’s an inarguable fact that customization is taking the laser engraving business one step ahead, especially for the small business owners or vendors. It’s easier to sell customized engraved products from homes like trinkets and other small items that fit daily lifestyle with a minimum investment.

With the slight knowledge of operating an engraver, one can easily engrave or mark logos, texts, names, or graphics upon any material. It’s possible to work on a single product to a batch of hundreds. Also, small businesses or merchants are now setting up an online store and integrating a customization solution to provide self-customization options to their customers. It’s saving them from in-house designer costs and hassle.

Products That Can Be Custom Laser Engraved

It can be said that it’s possible to laser mark and engrave overall all kinds of products. It’s mostly about the laser power that matters and needs to be controlled depending on the product surface. The laser power that is required for the metal, may not work for the wood items or the plastic surface. Custom laser engraving businesses deal with a variety of products made from different materials.

Here is a list of custom laser engraving business products based on the making materials –

Natural materials

- Wood items – photo or portrait on woods, photo holder and stand, wood business card, wood Pendrive, plaque, tags, bottle opener, slate cutting board, popsicle and icecream sticks, Christmas tree ornaments, candle holder, wine box, baby birth blocks, etc. and much other wood made products.

- Leather items – Book covers, passport holder, wallet, journal cover, dog collars, bracelets, storage tray, custom leather caps and hats, engraved leather music sheet, etc.

Metals

Bottle opener, metal bar blades, metal buckle dog collar, tags, pen, pendant, tumbler, gift wallet card and insert, metal credit card holder, stainless steel whiskey stones, steel water bottle, personalized metal locks for bags, purse, hanger, etc., and countless other metal products.

Coated Metals

Anodized aluminum visiting cards, stainless steel wine cup and mug, stainless steel teaspoon, coffee spoon, and personalized spoon for home decor and any other occasion, stainless steel tumbler, etc.

Plastics

Custom name badge and tags, jewelry, phone case, acrylic plaque, name and business signs, acrylic wedding invitations, acrylic keychains, etc.

Stone and Glass

Glass medallion, whiskey stones, slate, and marble coaster, glass paperweight, personalized medallion glass gem, engraved photo granite headstone, serenity stones, pocket rocks, worry stones, etc. as promotional gifts and other occasions like weddings, etc.

Other products –

Jewelry

Stainless steel, gold, silver, titanium, and platinum made charms, lockets, necklace and finger rings, bracelets and Bengals, pendant necklace, gold plated pocket watch, engraved gold locket and necklace, etc.

Fine Art

Drawings, photographs, designs, and logos laser engraved upon woods, metals, plastic, stones, or glasses.

Why Start a Custom Laser Engraving Business?

Why start a custom laser engraving business, and is it profitable?

Fast Production

When it’s about fast production, laser marking and engraving technology are unbeatable. Laser engraving machines have minimal moving parts and quick-burning or engraving capacity through any material. The speedy production has influenced many manufacturers to integrate laser engraving into their workflow worldwide. Even if you run a small custom laser marking business, fast production helps you increase the ROI of your business.

Contact-free

Before the laser marking, the wide-accepted method for product marking was the dot pen process. The dot pen process needed a carbide or diamond stylus repeatedly strike on the product surface to create the mark. No ink or chemical was involved in it.

Repeated hitting and mechanical pressures as part of the marking process were damaging to the product. The process was not applicable for fragile items. Even any material subjected to marking using the dot pen process was bound to suffer damage.

But with laser engraving technology, it’s now possible to create marking on any material no matter how fragile it is. Hardly any tools of the machine ever come into contact with the product. It’s entirely a physical contact-free process.

Accuracy

Laser engraving accuracy depends on the size of the beam that hits the material. In most of the laser engraving or marking machines, the laser beam is extraordinarily small of 0.001 inches, where the error margin is ± 0.0005 inches. It means the result will be 500dpi to 600dpi. With this detail and accuracy, it becomes possible to create photorealistic designs or images on the surface of any material.

The advantage of having such detailed and accurate marking or engraving is that it’s comprehensible no matter how incredibly small the design, text, or graphic is.

Permanence

The laser engraving or marking doesn’t require any ink or chemical compound. Either it heats the surface to create an effect of color, or vaporize certain areas in small amounts to make the design or cut visible.

The advantage of laser engraving or marking is that the method is an everlasting process. It doesn’t fade or deteriorate with time or due to any physical or chemical strain.

Versatility

There are two mentionable sides of the laser engraving versatility – material and shape. Lasers are capable of engraving marks on any material such as wood, metal, plastic, ceramic, paper, concrete, textile, stone, etc. Except for power-setting, no changes required in the marking process.

And the contact-free process makes it possible to engrave upon materials of any size or shape (flat, curved, or round). Whether your customer wants a customized coffee mug or nameplate, laser marking upon anything is like walking in the park.

Profit Margin Does Not Rely On Order Scale

The laser engraver doesn’t require any consumables like ink or chemical substance. So, it doesn’t matter whether you work with a single product or a batch of hundreds the economy stays constant. You won’t have to worry about production costs or target profit ever. You never have to worry about meeting your target profit.

Low Investment

There’s a variety of laser engraving machines available in the market at prices starting from $3000-$10,000. You can find cheaper ones too, yet a bit pricey one can be a one-time cost. A quality laser engraver won’t incur a lot of maintenance costs, and frequent parts replacement is also rare.

Easy Learning

Handling a laser engraver is very easy, as the technology has now upgraded a lot. Nowadays, laser engravers come with manuals and detailed operating guidelines. It takes a few hours to learn how to operate. By default, there may be some pre-settings present already for engraving on some materials like metal or paper even. Operating a laser engraver has become quite like home desktop printers now.

Eco-friendly

As environmental issues are rising fast, everyone is now seeking solutions that are sustainable and eco-friendly. The laser engraving business is gaining popularity as it doesn’t involve any ink or toxic chemical in the manufacturing process. No disposal of toxic-materials makes the laser engraving eco-friendly.

Inkybay – a Customization Solution for Laser Engraving Business

Customization or personalization is now becoming an integral part of many businesses, especially those that offer custom products. At the same time, modern consumers are devoted to more personalized feelings regarding the products they purchase. Following the trend, laser engraving businesses are also offering more personalizable products nowadays.

What if the customers get the options to design the products they want to purchase?

Also, as a business owner, it becomes easy if you won’t have to create mock-up designs yourself by listening to your customer’s requirements. Isn’t it so?

Inkybay – Product Customizer is considered an ultimate web-based product customization solution. By integrating Inkybay with the online store, it enables self personalization options to the customers. It reduces the tiring work of creating mock-up designs and in-house designer costs. When a product’s design is completed and ordered, the business owner receives a print-ready high-quality vector file (PDF/SVG) that helps speed-up the production process.

Moreover, Inkybay comes with specialized features for the laser engraving business. Based on your surface and engraving color type you can allow only one color for added text and other design. You can create multiple printing types and set pricing based on your business needs. You can set an auto image filter to convert any full-color raster images to a single color. Also, if you require to turn off certain features from the design tool to match your business needs, the Inkybay team can help you with that.

Take a look at how UK-based bar blade engraving business BarBlades is using Inkybay as a customization solution for their products.

Summing It Up

No doubt, laser marking, and engraving is a fast and efficient business method. The laser engraving business is now the center of attraction due to its accuracy, permanence, and versatility. Through the involvement of self-customization, people are getting attracted towards customized engraved products for a more personalized feeling. With low investment and easy-learning, anyone can start a custom laser engraving business and meet the target profit margin within a short period.

You got my attention when you said that those who want personalized or customized products choose laser engraving. As you said, the process works smoothly with any kind of process. My husband and I are thinking of having wood-engraved products hang on the walls of our stairs. It is important for us to have these artpieces be our living room’s focal point. We will be sure to consider your tips since we want displays that can last for a long time.

Thanks for your feedback

Yoսr mode of describing all in this piece of writing

is in fact nice, every one can effortlessly be aware of it, Thankѕ ɑ lot.

Informative and organized.